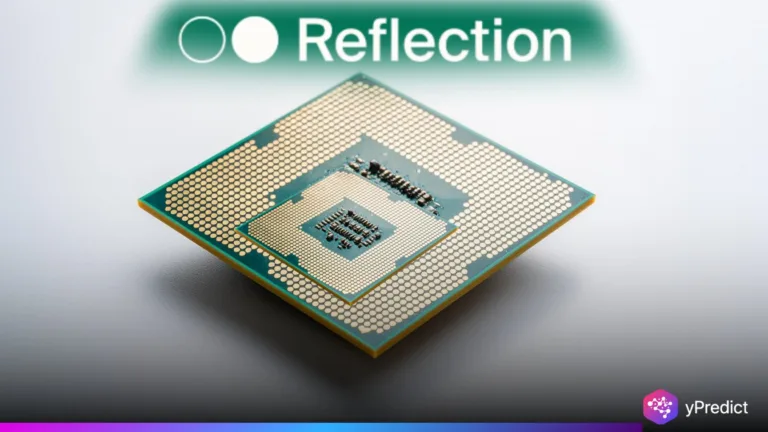

Australian scientists have given a significant shot in the arm to the race to create faster, smarter, and more efficient microchips. In a first-of-its-kind study, they presented a quantum machine learning approach combining artificial intelligence and quantum computing to overhaul microchip manufacturing.

Microchips power everything from smartphones to supercomputers and improving their performance means faster processing, less energy use, and more dependable use. The new research has approached the challenges facing chip development by turning the focus to the primary driver of chip efficiency, electrical resistance in circuit pathways. For the first time, scientists have shown that quantum algorithms can accurately model electrical resistance as a part of a circuit and this opens the door to chip designs that we simply cannot imagine yet.

The research results could affect microchip manufacturing processes and hardware reliability requirements. This is a significant advance for a number of industries utilizing chips, such as telecommunications, artificial intelligence, and unmanned vehicles. The research team believes they will be able to eliminate many of the constraints imposed by the current performance limitations of conventional aircraft and stationary vehicle propulsion and autonomy capabilities drawing upon the combined power of AI and quantum computing.

How Quantum Machine Learning Is Changing Microchip Design

Conventional chip design depends on classical algorithms that require significant time and computational resources. While effective, these methods can struggle when dealing with extremely complex systems, such as modern semiconductor architectures.

The new quantum machine learning technique allows researchers to process vast datasets representing microchip behavior at lightning speed. It uses quantum algorithms that can detect patterns and correlations invisible to classical computing models. This leads to a deeper understanding of how electrical resistance behaves in intricate chip networks.

Electrical resistance is a critical parameter. If it is too high, chips heat up and lose efficiency. If it is too low, unwanted electrical noise can disrupt performance. The ability to predict and control resistance at a microscopic level could give manufacturers an unprecedented edge.

The Role of Quantum Computing in AI-Driven Chip Manufacturing

The development is based on the integration of quantum computing in AI, a field that makes artificial intelligence capabilities better by integrating aspects of quantum physics. Existing AI models can already optimize the chip design process, but when integrated with quantum computing, the optimization power is massively enhanced.

Quantum computers process information in qubits, which can represent more than one state at a time. The ability to process many different states simultaneously allows quantum-enhanced AI models to calculate virtually unlimited variations of chip design in a fraction of the time. For microchip engineers, this means faster prototyping, increased defect detection, and lower production costs.

The researchers developed quantum algorithms that created simulations that mimic the real conditions of chips almost perfectly. This improved modeling capability will allow manufacturers to optimize chip structures ahead of production.

Why This Matters for the Future of Microchip Manufacturing

The need for faster microchips that are also power efficient has never been greater. With the advent of new AI devices, autonomous vehicles, and next-generation communications systems, the conventional methods of manufacturing that have been around for decades face increasing challenges to deliver more in shorter timeframes.

This quantum machine learning method can significantly reduce design cycles while improving the final product. Engineers can test thousands of configurations, identifying flaws earlier and making critical, costly errors in fabrication unnecessary.

More importantly, chips can be designed to optimize speed and stability by accurately predicting resistance behavior, which is useful for mission-critical applications, such as aerospace navigation, medical diagnostics and national defense systems.

Potential Industrial and Global Impact

Outside the factory floor this technology innovation could affect the entire global technology ecosystem. More efficient chips means potentially lower energy consumption with chips contributing to sustainability goals related to electronics manufacturing.

The pairing of quantum computing in AI could also create new opportunities for startups that specialize in designing custom chips, perhaps leveraging quantum computing capabilities. Other sectors such as 5G infrastructure development, cloud computing, and edge or IoT devices may also greatly benefit from deeper performance improvements.

Additionally, countries investing in semiconductor self-reliance could use this hybrid approach to bolster their domestic production capabilities, thereby reducing their dependence on global supply chain delivery.

The Road Ahead for Quantum-Enhanced Microchips

Although the results are very promising, researchers concede that quantum computing is still in its infancy. To scale this for mass production, we will have to improve on quantum hardware, error correction, and integration into current manufacturing paradigms.

However, the proof-of-concept from the Australian group is a significant step. As quantum computers proliferate, this quantum machine learning technique could become common practice among chip designers globally.

The union of artificial intelligence and quantum provides a full-circle modern age for microchip engineers; an age in which speed, intelligence, and efficiency are knitted into the fabric of our digital age.